NO.1698 Zhenluo Road,Jiaochuan Street, Zhenhai, Ningbo City, Zhejiang, China

+86-574-86452780

+86-574-86456328

sale1@nhbearings.com

For every industry, lubrication is vital to the performance of rotating equipment; when over 40% of maintenance cost are related to poor lubrication, proper management is crucial. The right quantity of the right lubricant applied at the right intervals is essential to achieving optimum application performance and maximum service life.

Now we have more than 300 years of experience in managing lubrication and reducing friction. And with our pioneering process technology for uncompromised industrial oil regeneration, you can reuse your oil over and over again.

No matter where in the lubrication management journey you are, you can boost the performance that matters to your business. Find out how.

Poor lubrication accounts for over 36% of premature bearing failures

Our lubricants are designed for your needs and tested for performance in real applications. Our experience with bearings, lubricants and applications helps us to offer the right lubricants for your applications and improve your overall lubrication scheme.

Testing and validating each production batch is our way to offer excellent lubricant quality around the globe.

Specialized lubricant tests and continuous research in the field of lubrication allows SKF to further optimize our knowledge and support you with right lubrication for your machines.

Lubricants offer major advantages:

Basic elements of a lubrication scheme

The main purpose of manual lubrication is to ensure accuracy and optimal cleanliness. The lubricating film in the application is more than 40 times thinner than the smallest visible particulate matter.

The series of manual lubrication tools is designed to store, handle, refill and supply lubricants to your equipment in a clean and easy way.

Automatically supply a small quantity of clean grease or oil to a lubrication point on a regular basis, thus improving bearing performance.

The right lubricant, in the right quantity, at the right time, to the right lubrication point.

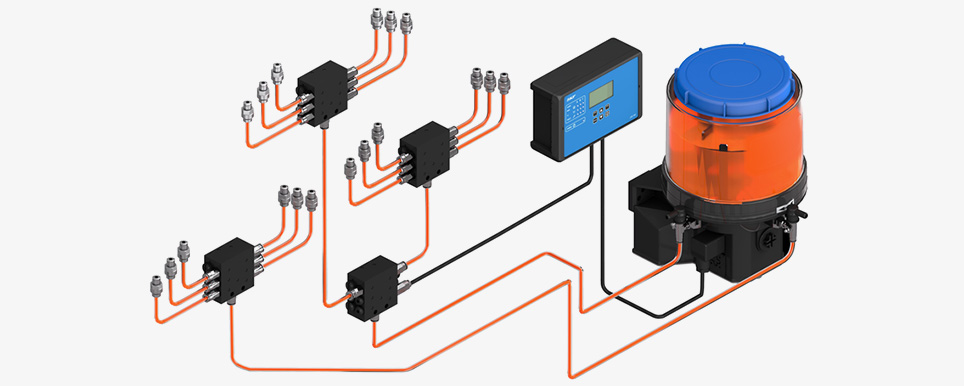

Centralized automatic lubrication systems are an effective way to increase machine availability while reducing reliance on scarce talent. These systems provide the appropriate lubrication quantity at the correct intervals, minimizing friction and wear and optimizing bearing and machinery service life.

Designed to lubricate individual machines or complete plants, automatic lubrication systems provide proper, precise lubricant replenishment to all required points, enabling a range of benefits in the process.

Benefits:

Applications:

NO.1698 Zhenluo Road, Jiao Chuan Street, Zhenhai, Ningbo City, Zhejiang, China

+86-574-8645 2780

+86-574-8645 6328

Copyright © 2019 NINGBO MOSHENG BEARING CO., LTD. All Rights Reserved.

Design By: HWAQ